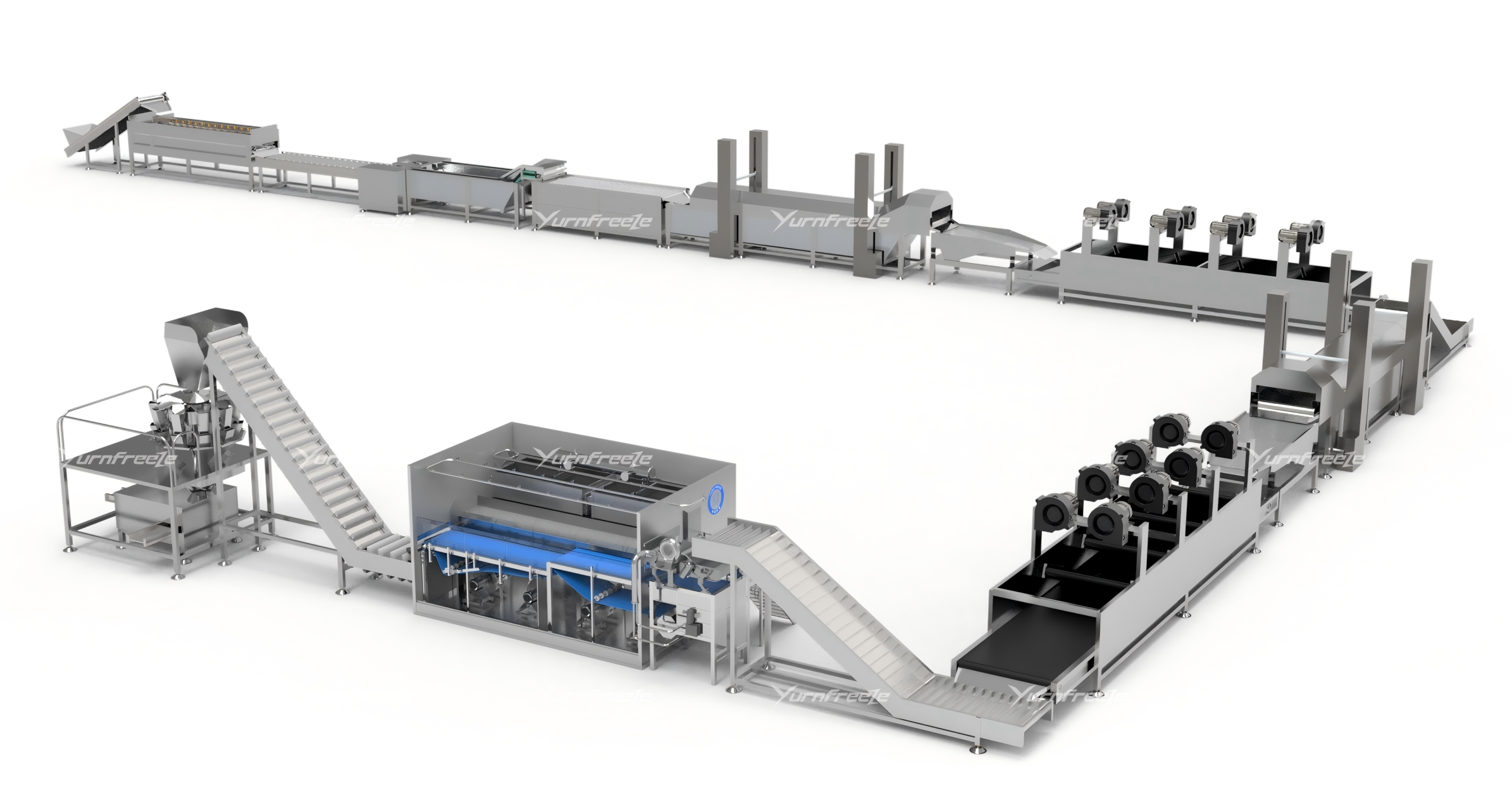

The French Fries Freezing Production Line is a complete automated system from raw potato preparation to frozen final product.

Suitable for large-scale producers, frozen food factories, and central kitchens.

Core Functions:

Core Functions:

Removal of soil, impurities, and potato skin

Drum or brush-type washing and peeling

Continuous feeding and discharge

Advantages:

High peeling efficiency with low material loss

Uniform cleaning for industrial production

Food-grade stainless steel, easy sanitation

Core Functions:

Core Functions:

Cutting peeled potatoes into uniform fries

Multiple cutting sizes available

High-speed continuous operation

Advantages:

Precise cutting for consistent product size

Easy blade replacement for flexibility

Reduced breakage and waste

Core Functions:

Core Functions:

Short-time high-temperature blanching

Enzyme inactivation and color stabilization

Preparation for freezing or frying

Advantages:

Accurate control of time and temperature

Continuous operation for high throughput

Improved product consistency and shelf stability

Core Functions:

Core Functions:

Removal of surface moisture

Prevention of ice formation and sticking

Improved freezing efficiency

Advantages:

Optional air drying or centrifugal dewatering

Reduced freezing load and energy consumption

Enhanced final product quality

Core Functions:

Continuous frying of French fries

Precise control of oil temperature and frying time

Suitable for par-fried or fully fried products

Advantages:

Zoned temperature control for uniform color

Continuous operation for high-capacity production

Reduced oil absorption and improved texture

Core Functions:

Removal of excess surface oil

Rapid cooling after frying

Preparation for freezing or packaging

Advantages:

Lower final oil content

Stable product temperature before next process

Designed for high-speed continuous lines

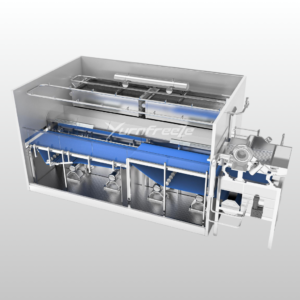

Core Functions:

Core Functions:

Rapid and uniform freezing of fries

Individual quick freezing (IQF) effect

Moisture and texture preservation

Advantages:

Fast freezing with minimal quality loss

Anti-sticking and low breakage

Ideal for large-scale production

Core Functions

Core FunctionsAutomatic weighing and packaging of fries

Multiple packaging formats supported

Direct integration with freezing or frying lines

Advantages

High-accuracy weighing reduces giveaway

Stable high-speed operation

Easy integration with metal detectors and sealing units

We will contact you within 12 hours, please pay attention to the email with the suffix “@yurnfreeze.com”.

我们将在12个小时内与您联系,请关注后缀为“@yurnfreeze.com”的邮箱。