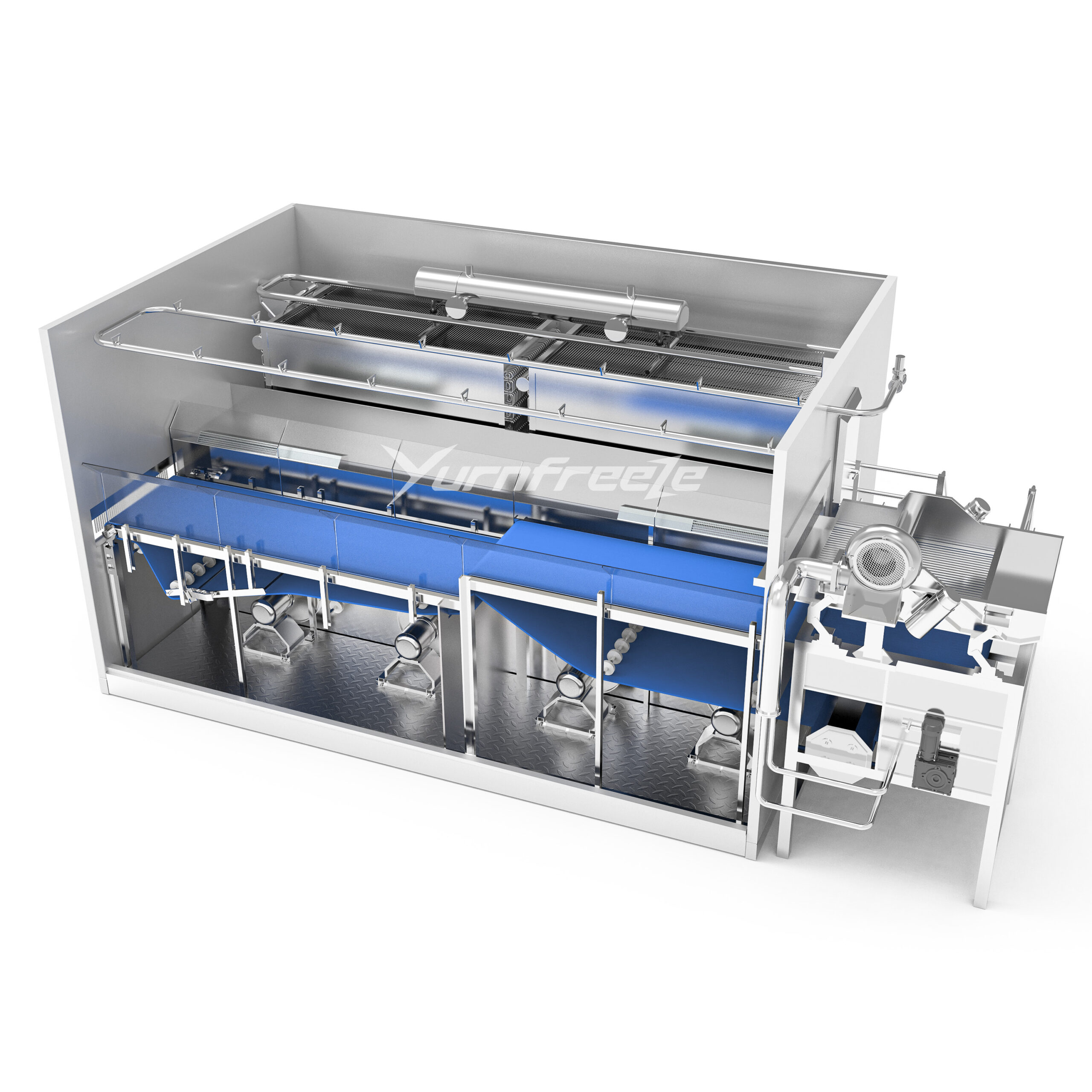

Dual Pressure Chambers:

Optimized Infeed Structure:

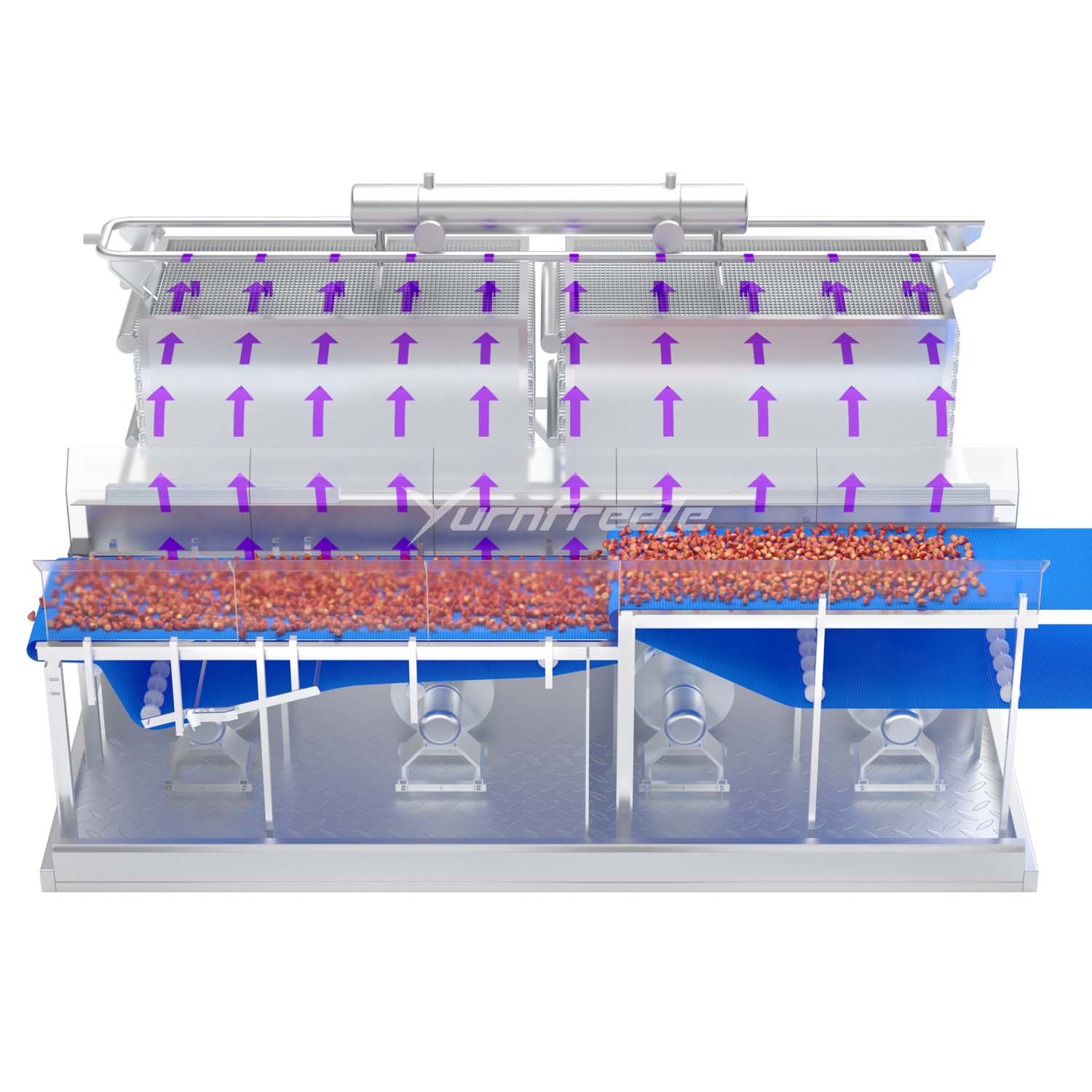

First Belt (Crusting Zone):

Second Belt (Deep Freezing Zone):

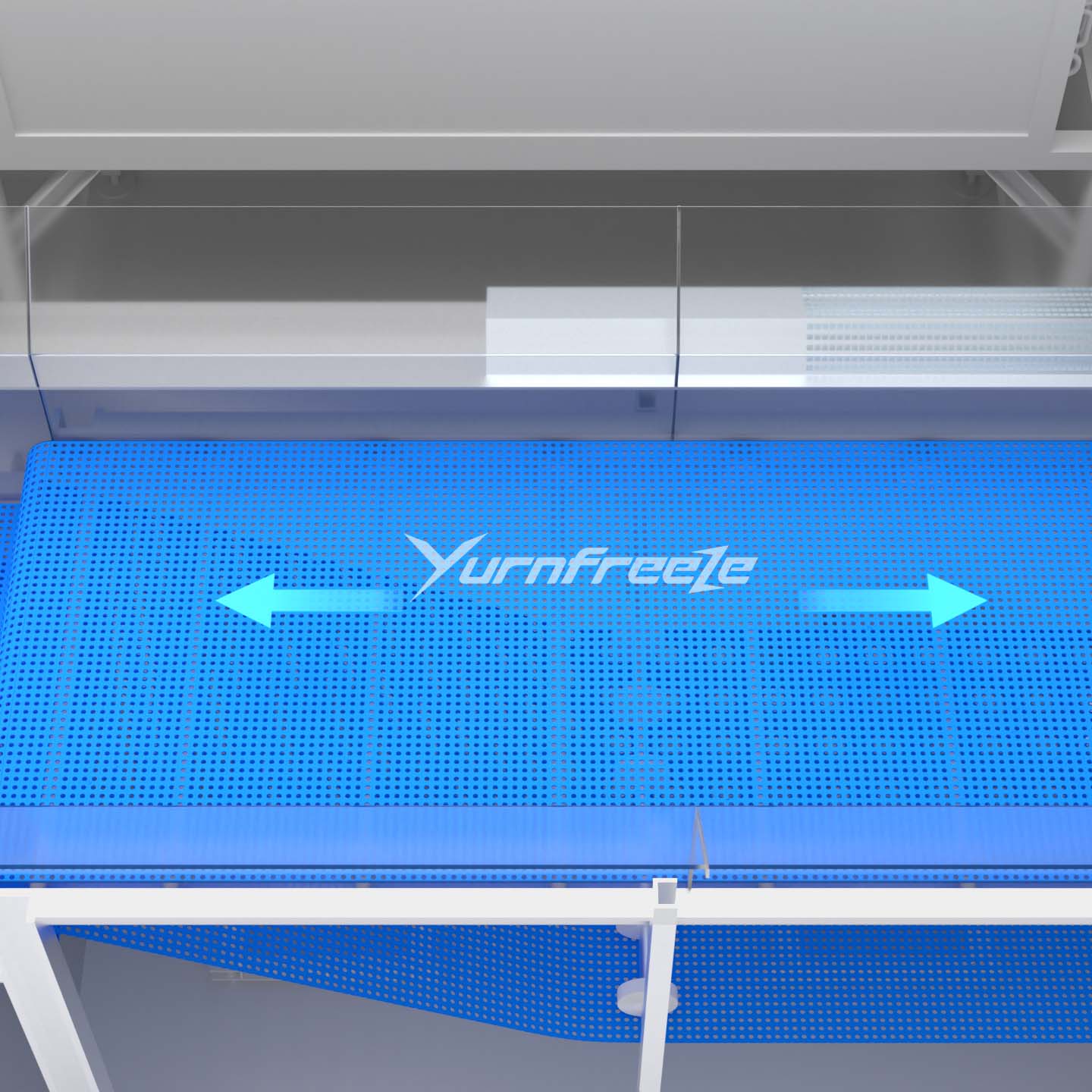

Advanced Innovative Pulsating Air System:

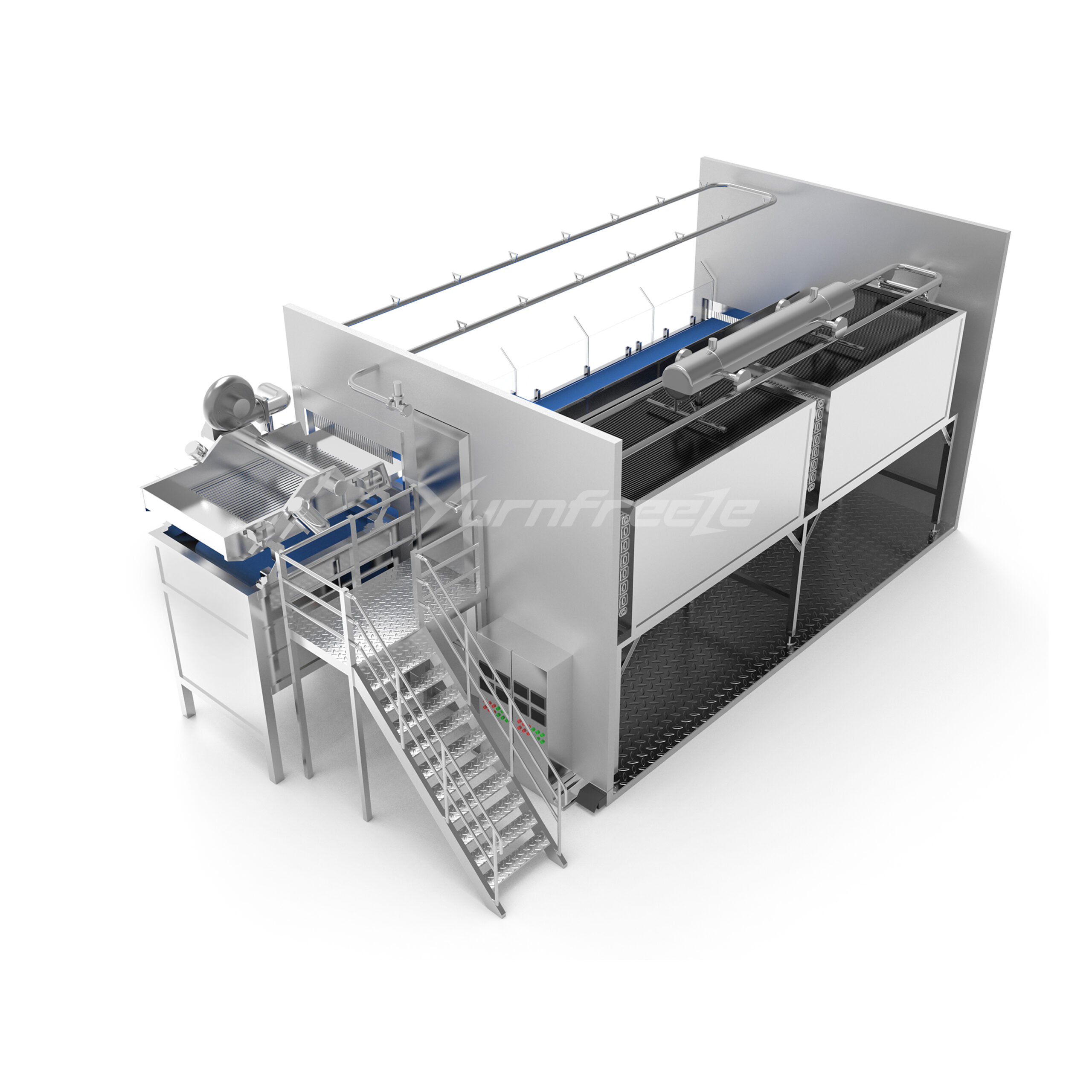

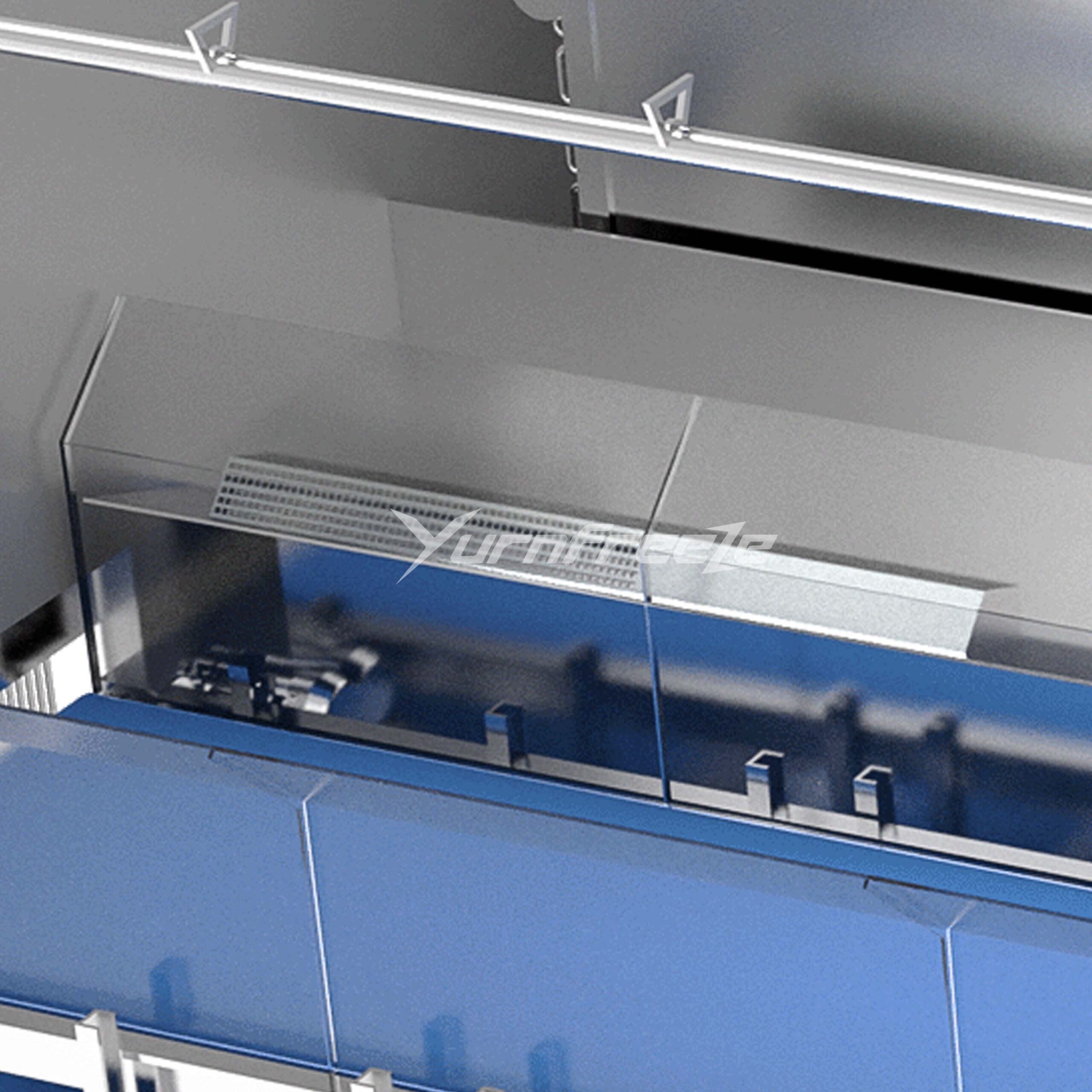

Intelligent Control System:

Advanced Defrost & CIP Options:

Optional Energy-Saving System:

We will contact you within 12 hours, please pay attention to the email with the suffix “@yurnfreeze.com”.

我们将在12个小时内与您联系,请关注后缀为“@yurnfreeze.com”的邮箱。